Roseville is home to an eclectic variety of buildings – from retail stores to warehouses, from modern homes to historic ones. These buildings provide function, security, and even personality to the city, and they need strong floors as a foundation. Contractors and builders examine the concrete they use to make sure it will hold up to the demands from Roseville citizens and business.

Still, concrete is not indestructible. It often suffers gouges, scrapes, cracks, and other damage that could compromise its integrity. That’s why so many homes and businesses in Roseville use epoxy coatings to protect and improve their concrete floors. Since epoxy coatings cover the concrete floors that take such a pounding, they need to be just as resilient – if not more so. Therefore, here are some examples of the types of tests conducted on the epoxy coatings used by West Coast Epoxy.

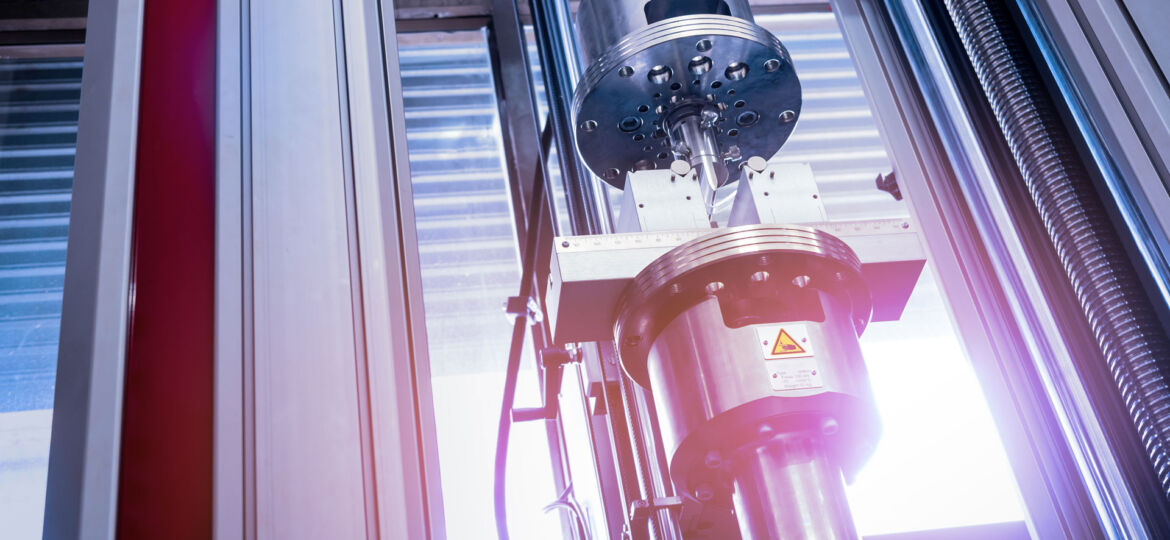

Epoxy Strength Tests

- Compression strength – this test measures the ability of the epoxy to handle being squished. Using a cured cylinder of the epoxy, both sides are pushed toward each other with an industrial press. (Concrete mixtures receive a compression test in the same fashion.) While concrete needs to keep integrity up to 3000 psi (pounds per square inch), epoxy coatings need to survive pressures up to 10,000 psi.

- Tensile strength – instead of pushing, this test pulls on the material. A cylinder of epoxy is pulled about by the ends. Concrete generally survives tensile stress at a rate that is 10% the compressive strength. That means if the concrete withstood 3,000 psi compression, it should withstand 300 pounds of tensile strength. For epoxy coatings, the ratio of compression to tensile is 35%, meaning that a coating which withstood 10,000 psi will usually withstand a tensile stress of 3,500 pounds.

- Flexural strength – this is like a tensile strength test, but it covers indirect stresses. Epoxy coatings often resist scrapes or gouges by bending or flexing, so testing their ability to endure pulls from different angles is important. Using a longer cylinder supported with braces on either end, a heavy load is suspended from the middle of the cylinder. Flexural strength for most epoxy coatings typically measures at around 5,000 psi.

- Bond strength – if the epoxy coating fails to adhere to the surface of the concrete, it cannot do its job, so performing a bond test on each batch of epoxy is vital. The bond strength of the epoxy must be greater than the tensile strength of the concrete beneath, so any failures happen from the concrete and not the epoxy. This test is often performed with a set of knobs embedded in a spread of the epoxy. Using a series of pulleys, the knobs are put under stress until they come loose. If the knob has concrete on the bottom instead of epoxy, the epoxy passes the test.

West Coast Epoxy uses tested epoxy, so every concrete floor in Roseville gets the best protection possible. That way, using epoxy coatings in Roseville is a tried-and-true way to protect and improve your concrete floors, and West Coast Epoxy is a great option for providing it. To find out more, give our office a call, or schedule a free onsite consultation using our online form.